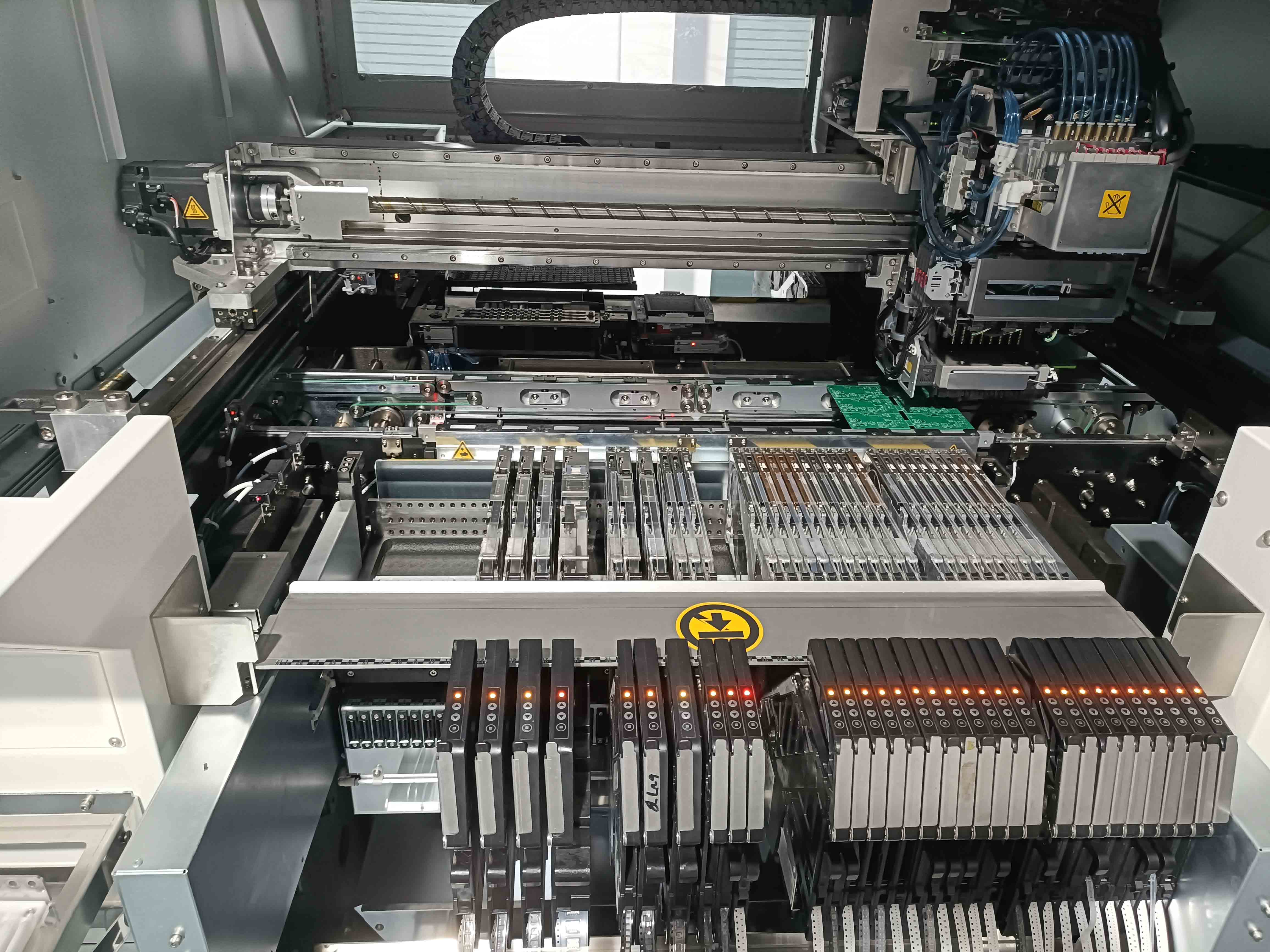

The opening ceremony of the new Surface-Mount-Tech production line

The nine different pieces of equipment start to work, including Solder Paste Printer, two Solder Paste Inspectors, Pick and Place Machine, Automated Optical Inspector, Reflow Oven, and Conveyor.

This significant enhancement in our production capabilities underscores our commitment to maintaining state-of-the-art manufacturing processes. The deployment of these advanced systems is essential for several reasons:

Enhancing Efficiency and Precision: Integrating cutting-edge technology into our production line significantly enhances both efficiency and precision. The advanced machinery facilitates faster production cycles and ensures the accuracy of component placement and soldering, thereby optimizing the overall manufacturing process.

Ensuring Quality and Reliability: Modern equipment is pivotal in maintaining rigorous quality control standards. The image monitoring and automated inspection systems detect and rectify defects promptly, ensuring that each product meets the highest quality and reliability standards.

Meeting Market Demand: The increased production capacity afforded by this new equipment enables us to scale our operations to meet growing market demand. This capacity expansion ensures that we can handle large orders efficiently while maintaining product quality and delivery timelines.

Staying Competitive: Continuous investment in advanced technology is crucial for maintaining a competitive edge in the industry. Upgrading our equipment not only enhances our production capabilities but also reinforces our reputation as an industry leader in innovation and quality. This strategic move attracts new clients and fosters stronger business relationships.

The addition of the new Surface-Mount-Tech production line represents a significant milestone in our ongoing efforts to enhance manufacturing efficiency, precision, and capacity. This investment reaffirms our dedication to leveraging the latest technological advancements to deliver superior products to our clients.